AERODYNAMIC DEVELOPMENT

Efficient aerodynamics is a key factor in determining race car performance. ADESS AG’s wide range of experience in aerodynamic development covers design, CFD (Computational Fluid Dynamics) , wind tunnel scale model design and manufacture, wind tunnel testing and data analysis, providing a full aerodynamic development. Such work is undertaken from preliminary studies in CFD through wind tunnel testing with well-established and proven methods and practices. Required vehicle simulation work is used to complement the aero programme by determining understood targets and desirable aerodynamic characteristics.

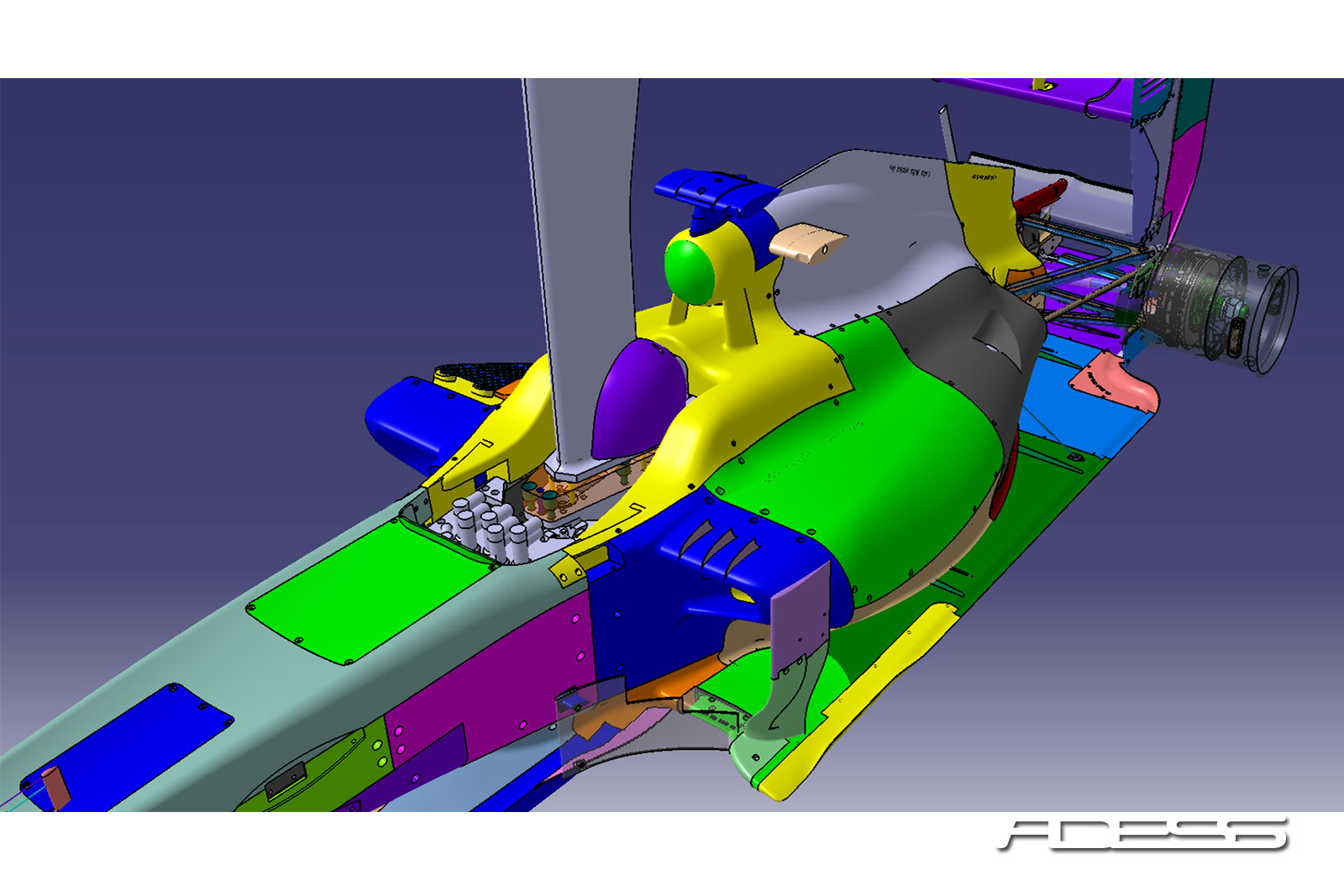

Highly detailed scale wind tunnel models are manufactured at ADESS AG's in-house model shop, utilizing advanced and trusted technologies to create parts that replicate the exact behaviour of their full scale counterparts. The use of stereo lithography “3D printing” technology enables rapid and accurate manufacturing of wind tunnel test components.

- Expertise in CFD (Computational Fluid Dynamics) , wind tunnel and track testing, allowing fully independent aerodynamic test programmes

- Aero surface design

- Computational Fluid Dynamics with Star-CCM+ and DOE techniques

- Design of wind tunnel models including mechatronic components

- Manufacturing of wind tunnel models, which includes the correspondent instrumentation

- Wind tunnel data analysis and reporting